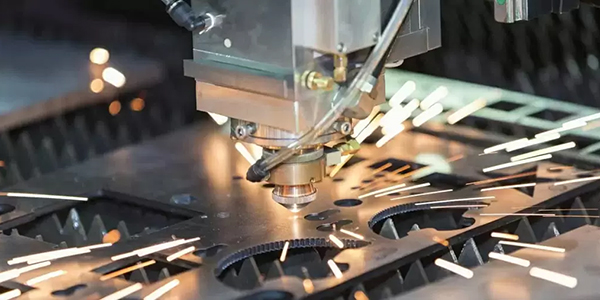

High Speed Laser Cutting

Re litsebi tsa ho itšeha ka laser le ho sebetsa ka mokhoa o sa sebetseng, lihlomo le lisebelisoa tsa High Strength Low Alloy. Mephato e kang Hardox (litekanyetso tse ngata tse bolokiloeng e le tsa khale), Weldox, Abrazo, Armox, le Invar & Abro kaofela li ka sebetsoa ho fihla ho 25mm botenya.

Re na le thepa e fokolang ea lisebelisoa tsena ho thusa ho fetola kapele. Re na le mefuta e mengata ea thepa ea khale ea Domex & Hardox mme re sebetsa lisebelisoa tsena khafetsa.

Ka kopo letsetsa bakeng sa lintlha tse ling le ho fumaneha ha stock ha joale.

Waterjet Cutting

Sistimi ea rona ea ho itšeha ea Waterjet e sebelisa metsi ho 50,000 psi le garnet e abrasive ho seha hoo e batlang e le thepa efe kapa efe, ho kenyeletsoa titanium! Lipompo tsa intensifier li fana ka matla a lipere tse 150, tse lumellang ts'ebetso e betere le ho feta lisebelisoa tse tenya. Melemo e meng ea waterjet e kenyelletsa: Bokhoni ba ho itšeha ka sebopeho se phahameng. Ho seha lisebelisoa mekhoa e meng e ke keng ea khona, joalo ka rabara ea foam, tile ea ceramic, 'mabole le khalase. E sebetsana le mefuta e mengata ea lisebelisoa habonolo. ± 0.005" ho nepahala ha boemo. E felisa masoba a ho kenoa esale pele. Mosebetsi o fokolang ho feta mekhoa e meng. O ka khaola lisebelisoa tse teteaneng haholo (Re sehile 8" koporo e teteaneng!).

Router e emeng

Ho khaola ho kopana ho fihla ho li-inch tse 3,150 ka motsotso.

• Mokhoa o potlakileng oa ho sebetsa aluminium, SS, CS le alloy Steel.

Tafole ea 72" x 144" e nang le enfelopo ea mosebetsi ea 84" x 140" le 15" ea maeto a z-axis.

• O ka kenya lisebelisoa tse teteaneng le likarolo ho fihla ho 6' x 12'.

Sistimi ea pholiso ea likhohola bakeng sa lisebelisoa tse thata ho isa mochining

• E lumella lebelo le holimo le litefiso tsa phepelo, e eketsa bophelo ba lisebelisoa, e fokotsa karolo ea litšenyehelo.

• Ho khona ho etsa machining tšepe e sa hloekang le titanium.

20-horsepower, HSK 63A spindle e pholileng ka metsi e nang le pholileng ka sesebelisoa le mochine o kopanyang oa lisebelisoa tse matla.

• Mokhoa o tsoetseng pele oa ho tšoara lisebelisoa.

• Ho pholisa ka sesebelisoa ho bolela ho cheka ho tebileng ka potlako.

• Liteishene tse 12 tsa lisebelisoa li lumella hoo e batlang e le mosebetsi ofe kapa ofe hore o etsoe ntle le ho lokisoa bocha.

40-horsepower pompo ea phallo e phahameng ea vacuum.

• Vacuum e ntseng e eketseha haholo e thusa ho tšoara lipoleiti tse teteaneng kapa likarolo tse ngata tse nyenyane sebakeng sa tsona.

± 0.0004" (0.01mm) ho pheta-pheta ka tsela e le 'ngoe le ± .0025" selikalikoe.

• Likarolo tse phethiloeng tse nepahetseng haholo.

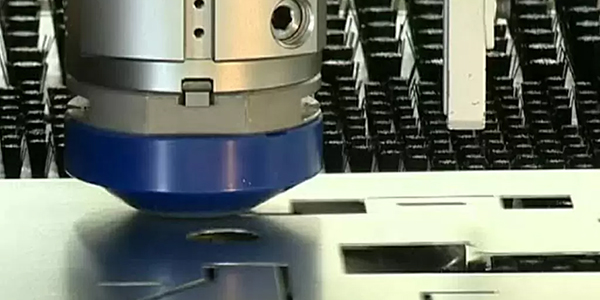

Tlhaloso e Phahameng ea Plasma Cutting

Ho itšeha ka plasma ho 'nile ha nkoa e le mokhoa o theko e tlaase ho feta oa oxy-fuel le laser profiling moo cut angle e neng e se bothata. Lintlafatso tsa morao-rao ts'ebetsong ea plasma e nepahetseng haholo / e phahameng e ntlafalitse boleng le bokhoni ba ho itšeha, ho etsa hore e be khetho e fapaneng le e nepahetseng ho feta leha e le neng pele.

Ho Tšoaneleha Kopo

Ho itšeha ka plasma ho loketse lisebelisoa tse fapaneng haholo-holo litšepe tse bonolo le litšepe tse se nang mochini tse hlahisang pheletso e ntle haholo.

Lintlafatso ho litsamaiso tsa taolo joale li bolela hore ts'ebetso e nepahetseng ea ho seha bakeng sa mefuta e fapaneng ea thepa le botenya ho tloha ho 1mm ho isa ho 50mm ka tšepe e bonolo (ho ipapisitse le matla a yuniti ea plasma) e ka finyelloa.

Mekhahlelo e amanang le ho khaola mefuta e mengata ea thepa le botenya joalo ka lebelo la ho itšeha, mefuta ea khase le likhatello tsa khase joale li ka laoloa ka bo eona ka lisebelisoa, ho netefatsa boleng bo phahameng bo sa fetoheng. Hona joale basebelisi ba na le mekhoa e meng e atlehang e le kannete ho mekhoa e meng ea ho itšeha.

CNC Punches

CNC Punching sheet metal work with CNC Punch tools le CNC Punch Presses. Khomphuta e laoloang ke linomoro (CNC) punching ke mokhoa oa tlhahiso o etsoang ke mechine ea khatiso ea CNC. Mechini ena e ka ba moralo o le mong oa seporo sa hlooho le sesebelisoa (Trumpf) kapa moralo oa turret oa lisebelisoa tse ngata. Mochini o hlophiselitsoe ho tsamaisa lesela la tšepe ka lehlakoreng la x le y e le hore o behe lakane hantle ka tlas'a pheleu ea mochini e itokiselitseng ho phunya lesoba.

Sebaka sa ts'ebetso bakeng sa mechine e mengata ea khatiso ea CNC punch ke 0.5mm ho 6.0mm ka har'a lisebelisoa tse ngata tse kenyelletsang tšepe, zintec, galv, tšepe e sa hloekang le aluminium. Khetho ea lesoba le phunyeletsoeng e ka ba bonolo joaloka selikalikoe kapa khutlonnetsepa ho ea ho libopeho tse khethehileng ho lumellana le moralo o itseng o sehiloeng. Ka ho sebelisa motsoako oa li-hits tse le 'ngoe le li-geometri tse fetang, libopeho tse rarahaneng tsa likarolo tsa tšepe li ka hlahisoa. Mochini o ka boela oa phunya liforomo tsa 3D joalo ka li-dimples, taptite® screw thread plunges, le li-knockout tsa motlakase joalo-joalo ka mahlakoreng a mabeli a lakane, tse atisang ho sebelisoa moetsong oa moetso oa tšepe. Mechini e meng ea sejoale-joale e kanna ea ba le bokhoni ba ho tlanya likhoele, ho mena li-tab tse nyane, ho phunya lithako tse betliloeng ntle le matšoao a bopaki a sesebelisoa ho etsa hore mochini o be le tlhahiso e ngata nakong ea potoloho ea karolo. Taelo ea ho khanna mochini ho theha karolo e lakatsehang ea geometry e tsejoa e le lenaneo la CNC.